|

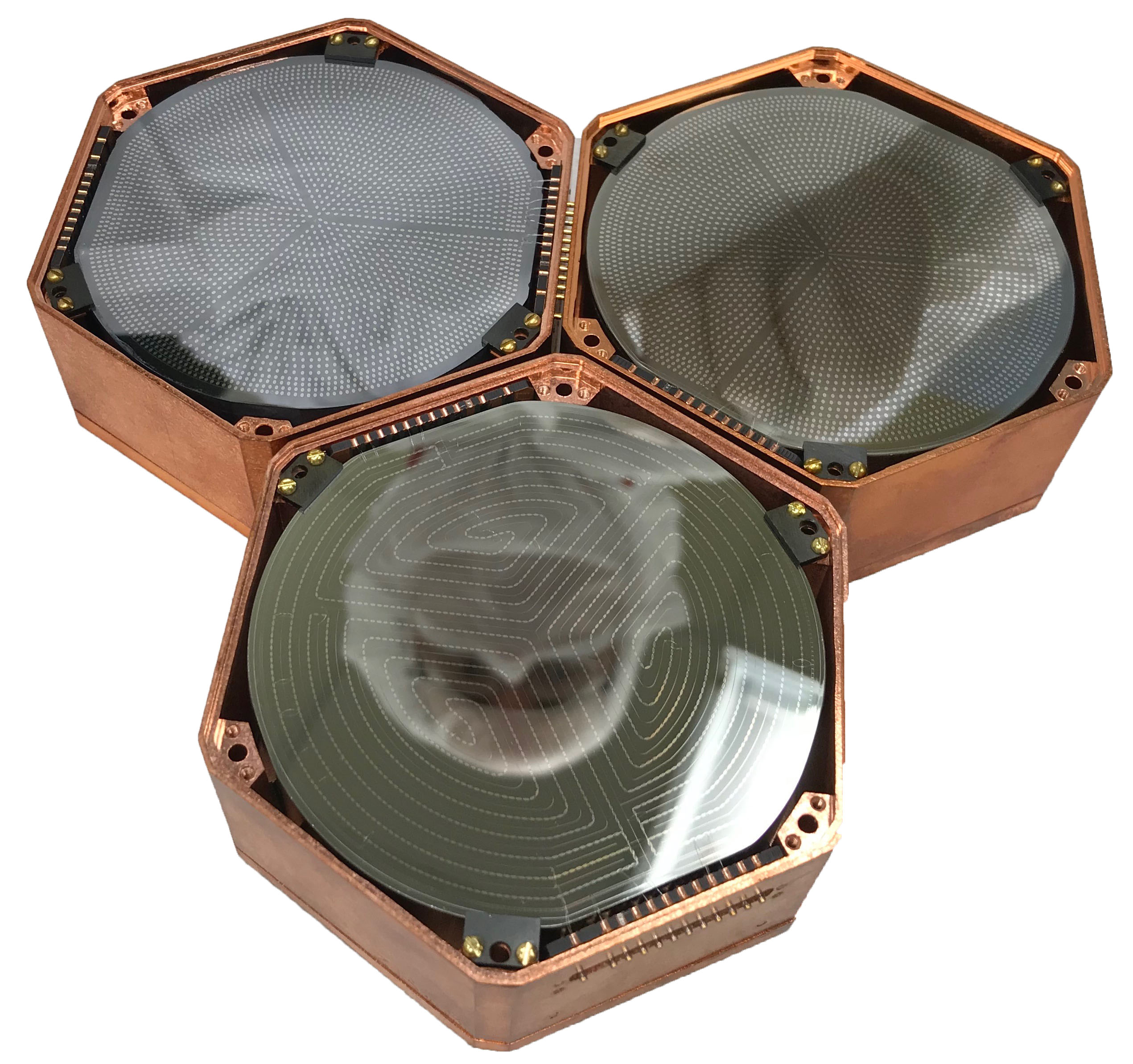

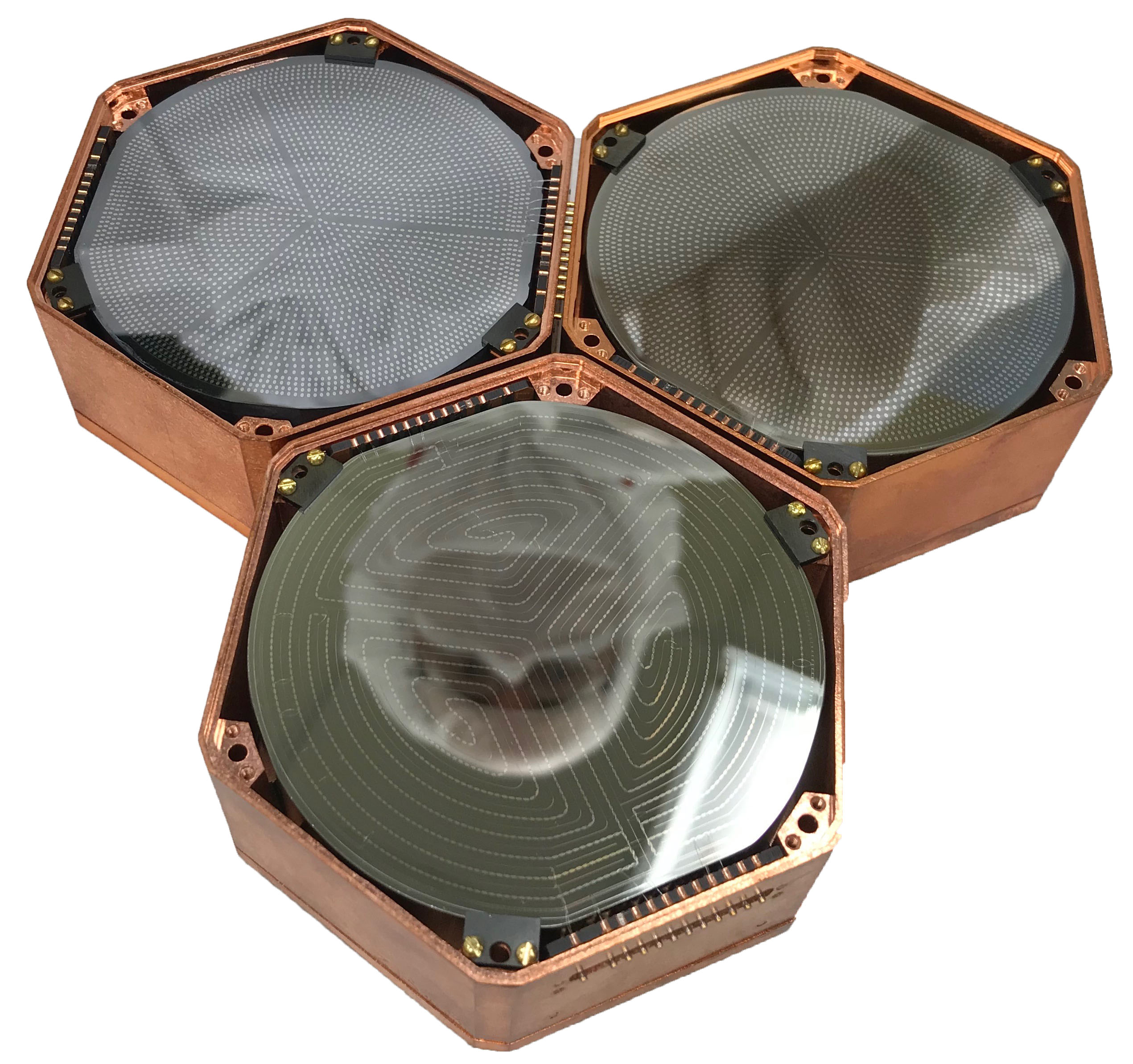

Photolithographically patterned semiconductor detectors with Transition Edge Sensors (TES) developed at TAMU. Our facility designs, fabricates and charcterizes

cryogenic detectors for SuperCDMS Dark Matter (DM) experiment as well as MINER Coherent Elastic Neutrino Nucleus Scattering (CENNS) experiments, as well as the

SPICE/HERALD New Initiatives in Dark Matter (NIDM) project as well as several Detector R&D projects in particle physics and QIS.

|

|

|

Semiconductor Engineering Group Inc (SEGI) sputtering system, capable of sputtering simultaneously on 8 six-inch wafers.

It has fully computerized controls, and has load lock with robotic movement of wafers from load lock to the sputtering chamber.

The instrument has 3 targets, one operated in DC mode, one operated in RF mode and the third configurable in either DC or RF mode.

Well established performance for many Dark Matter and Coherent Neutrnio Scattering experiments.

|

|

|

Bluefors LD400 closed-cycle cryogenic system that allows us to carry out detailed characterization of our detectors at a base temperature of 7 mK. The system allows us to cool down sample within 24 hours to base temperature (sometimes longer depending on the size of the detector).

|

|

|

Versatile deposition system by AJA.

|

|

|

Optical Associates Inc (OAI) 206 full mask contact aligner is used to transfer circuit patterns on to the thin films deposited on semiconductor wafers.

The OAI aligner is capable of doing photolithograhic patterns on wafers up to 6" in diameter, with an accuracy of 1 micron. This model is capable of

handling thick crystals for SuperCDMS/SPICE/HERALD/MINER experiments.

|

|

|

Solitec spin coater 5110c is used to spin coat the wafers with photoresist, before they are exposed under the OAI contact aligner. The spin coater is fully programmable and dispenses the photresist according to recipes loaded in to its memory.

|

|

|

The wet processing steps (such as etching) is performed in the wet bench, which has dedicated compartments for acid, water, base solutions. The wet bench has a dedicated exhaust. It also has a heated compartment, which can be used to etch material in a heated acidic environment.

|

|

|

The wafers are spin dried in the spin dryer, after wet processing.

|

|

|

The wafers are baked in these Blue M ovens, after photoresist deposition.

|

|